How is stainless steel made? Engineering Exploration

Steel is a strong and versatile metal. It is an alloy consisting of iron with a small amount of carbon and occasionally other elements. The carbon directly influences the steel's strength and durability. However, a vast array of different steels have been developed through the addition of other alloying elements such as chromium, nickel.

How is Steel Made? Metal Casting Blog

With two steel producers, and over 300 steel distribution outlets throughout the country and numerous fabrication, manufacturing and engineering companies, the Australian steel industry generates $29 billion in annual revenue and is an essential part of the Australian economy. The Australian steel industry is a vital and sustainable source of.

How Is Steel Made

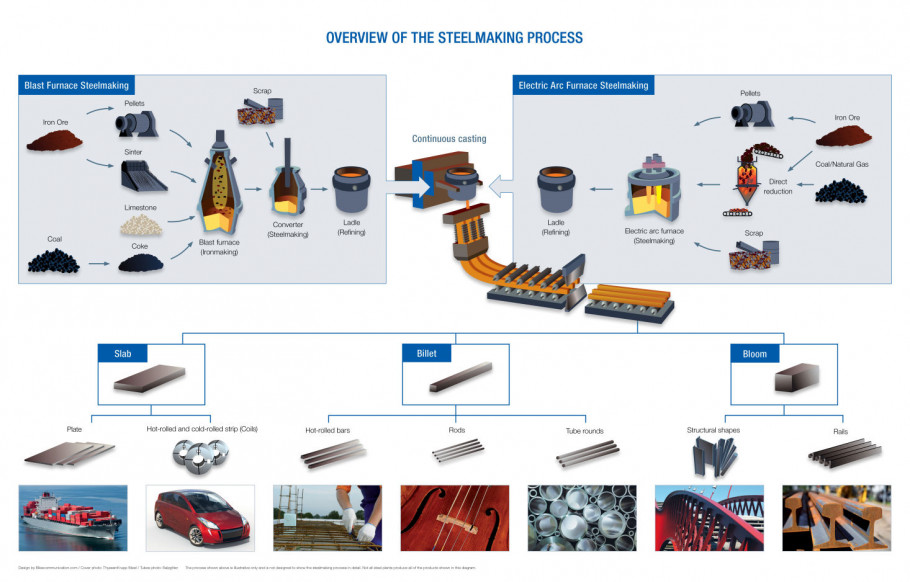

Ladle injection. Degassing. CAS-OB (composition adjustment by sealed argon bubbling with oxygen blowing) Continuous casting sees the molten steel cast into a cooled mold, causing a thin steel shell to solidify. The shell strand is withdrawn using guided rolls, then it's fully cooled and solidified. Next, the strand is cut depending on.

Steel Factory, Steel Production, Steel Making Process, How it's Made YouTube

Steel is an alloy of iron and carbon with improved strength and fracture resistance compared to other forms of iron. Because of its high tensile strength and low cost, steel is one of the most commonly manufactured materials in the world. Steel is used in buildings, as concrete reinforcing rods, in bridges, infrastructure, tools, ships, trains.

How is steel made? ShapeCUT

stainless steel, any one of a family of alloy steels usually containing 10 to 30 percent chromium. In conjunction with low carbon content, chromium imparts remarkable resistance to corrosion and heat. Other elements, such as nickel, molybdenum, titanium, aluminum, niobium, copper, nitrogen, sulfur, phosphorus, or selenium, may be added to.

The Different Types of Stainless Steel

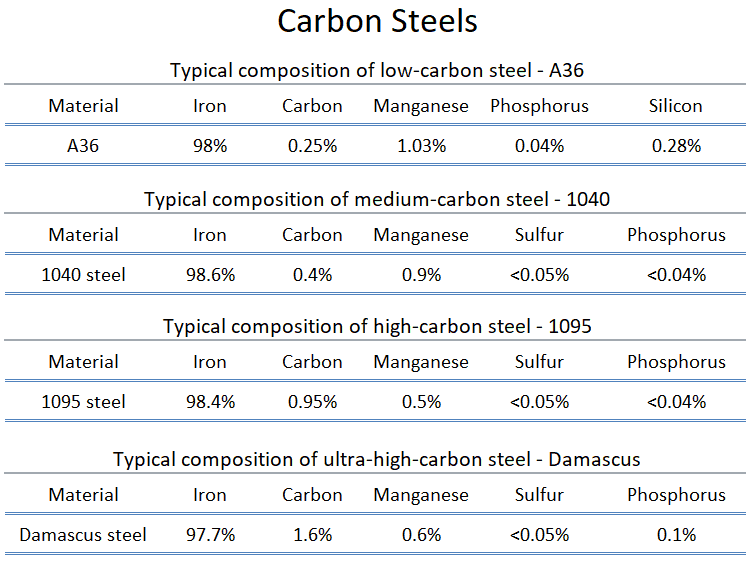

What is steel? Iron is made by removing oxygen and other impurities from iron ore. When iron is combined with carbon, recycled steel and small amounts of other elements it becomes steel. Steel is an alloy of iron and carbon containing less than 2% carbon and 1% manganese and small amounts of silicon, phosphorus, sulphur and oxygen. Steel is the.

WHAT IS STEEL? (Part 2)

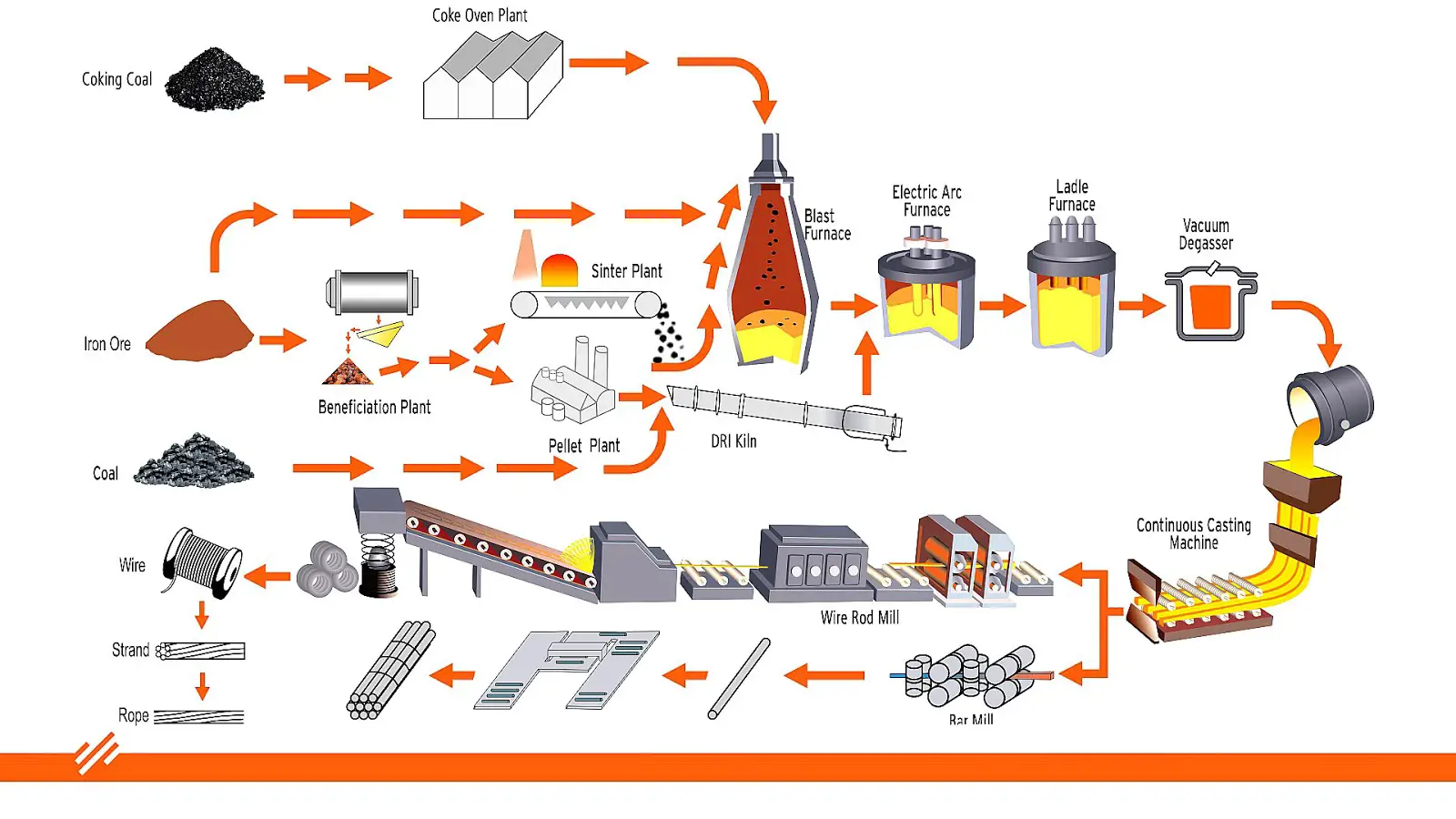

Overview of the steel production process. Steel is principally made via two routes, the last Furnace-Basic Oxygen Furnace (BF-BOF) route and the Electric Arc Furnace route (EAF) - often referred to as the 'primary' and 'secondary' paths. The former is used to create new or 'virgin' steel, the latter is often used to recycle steel scrap.

What is steel and how is steel made?

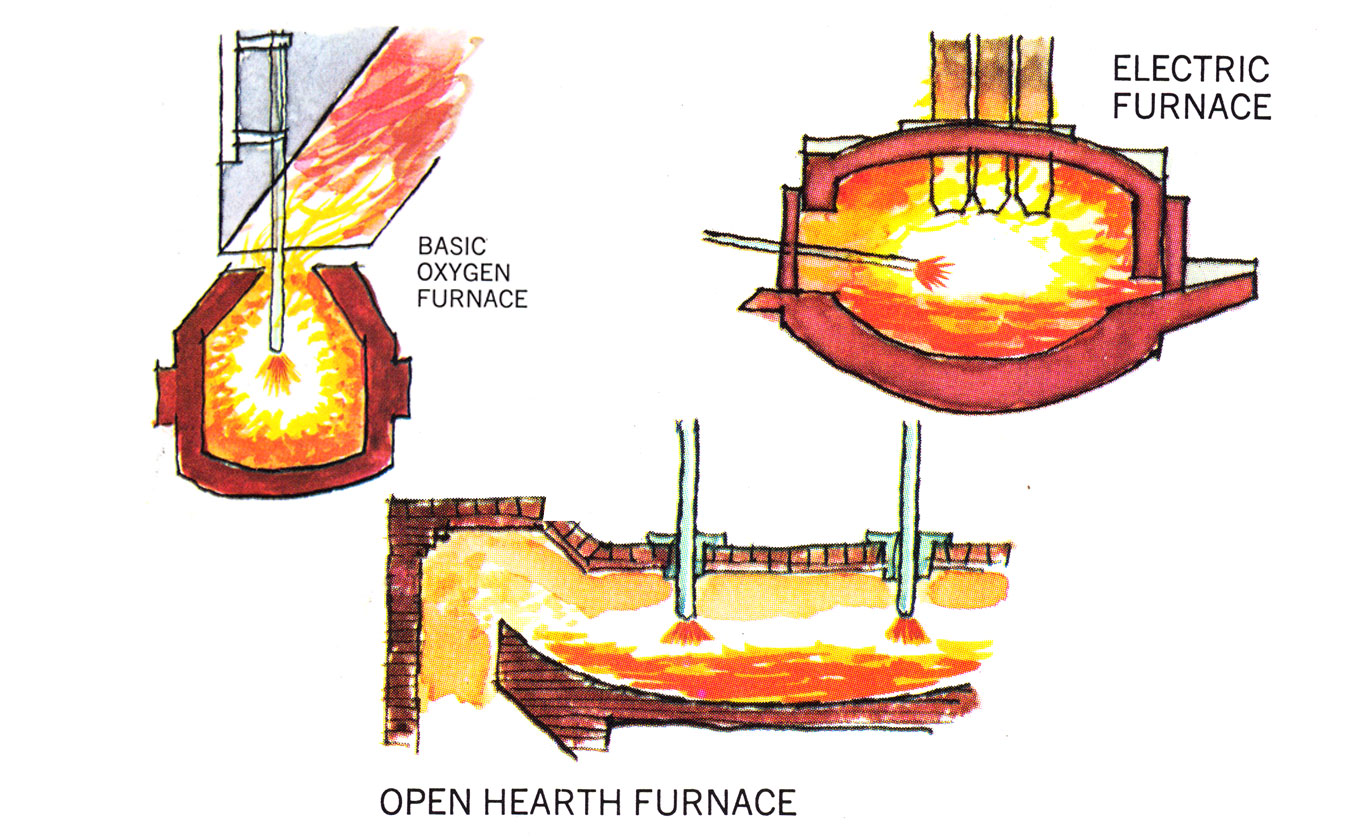

At the most basic, steel is made by mixing carbon and iron at very high temperatures (above 2600°F). Primary steelmaking creates steel from a product called "pig iron.". Pig iron is smelted iron, from ore, which contains more carbon than is correct for steel. The steelmaker uses a system that bubbles oxygen through melting pig iron.

Steel Making & Processing MechanicsTips

Another popular additive is chromium, which can be added to make stainless steel that's very resistant to rust. Steel is one of the most common building materials in the world, because of its high strength and relatively low cost to produce. Each year, steel plants produce more than 1.3 billion tons of steel that gets used in various.

¿Cómo se fabrica el acero? Blog de Fundición de Metales

Steel, alloy of iron and carbon in which the carbon content ranges up to 2 percent (with a higher carbon content, the material is defined as cast iron). By far the most widely used material for building the world's infrastructure and industries, it is used to fabricate everything from sewing needles to oil tankers.

Guide to Understanding Steel Materials Talk Series YouTube

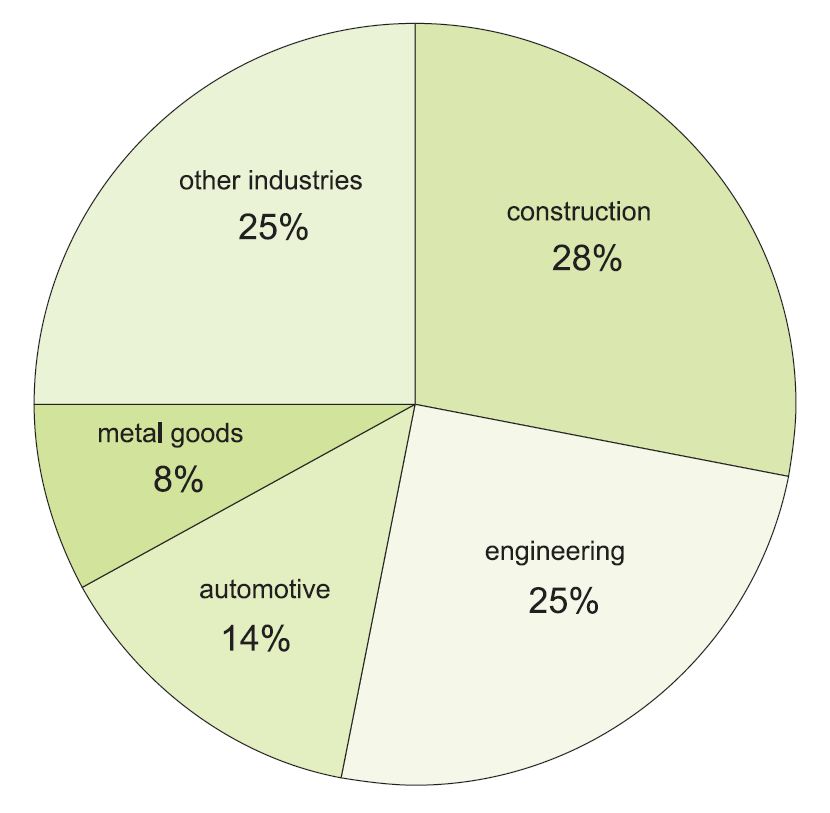

Steel is an alloy of iron and carbon that has been heat-treated to improve its strength and toughness. The carbon content in steel typically ranges from .2% to 2.1% by weight, which influences its properties, such as hardness and ductility. Steel finds extensive use in construction, manufacturing, automotive, infrastructure, and many other.

A Guide To How Sheet Metal Is Produced Radshape Limited

Steel Manufacturing Process. To produce steel first the iron ore is heated and melted in a furnace. The impurities are then removed from the molten iron. Carbon and other required alloying elements are added to make steel. Modern-day steelmaking is highly improved and specialized.

Infographic 20 Common Metal Alloys and What They're Made Of

This World Steel Association fact sheet describes the raw materials needed to make steel and how the extraction, transport and production of raw materials impacts on the environment. Key raw material inputs include iron ore, coal, limestone and recycled steel, 2018 version. Also see www.worldsteel.org

Steels Properties of Steels

Steel is made of an alloy of iron and carbon in which the carbon content ranges up to 2 percent (with higher carbon content, the material is defined as cast iron). Iron, the major elemental component of steel, is one of the most plentiful elements in the earth's crust. All steel alloys are primarily iron and 0.002-2.1 % carbon by.

Steel

How Steel Is Made. Steel is primarily produced using one of two methods: Blast Furnace or Electric Arc Furnace. The blast furnace is the first step in producing steel from iron oxides. The first blast furnaces appeared in the 14th century and produced one ton per day. Even though equipment is improved and higher production rates can be achieved.

How Is Steel Made? Steel Fabriction Services

Steelmaking. Steel mill with two arc furnaces. Steelmaking is the process of producing steel from iron ore and/or scrap. In steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (the most important impurity) are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon and.

.